Products

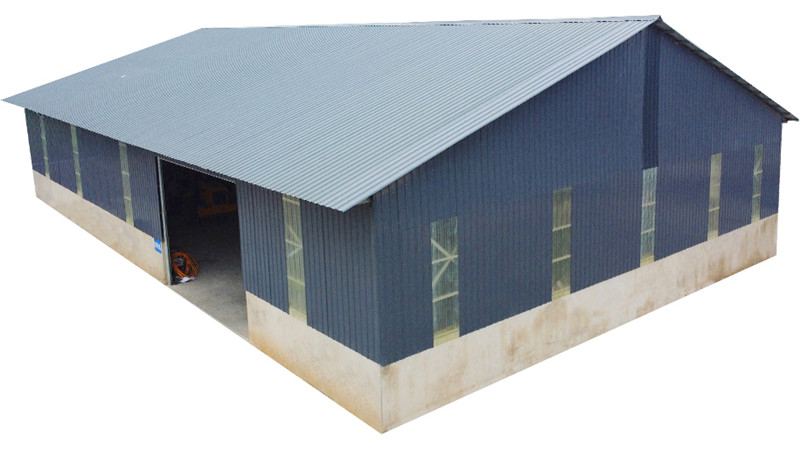

Standard Steel Structure Workshop

Main steel structure frame

The client told us the project located in a place where often have big wind storm with wind speed 120km/h sometimes, so we our structure design engineer use bigger specification to enhance the main structure, and imitate the 120km/h wind pressure by software to ensure building safety in big wind.

Steel support system

Because we already use bigger specification steel material at the main structure, and the building cost is big, so we recommend client cut some support steel to save cost, but premise condition is building safety guarantee.

Wall & Roof covering system

Roof purlin: galvanized C section steel, specification: C160*50*20 with thickness 2mm

Wall purlin: galvanized C section steel, specification: C160*50*20 with thickness 2mm

Roof sheet: V840 steel sheet with thickness 0.4mm, consider client need a good sunshine view inside the workshop, we recommend client install some sky panel as the follow picture.

Additional system

Rain gutter: This workshop roof is big, we recommend client install a gutter to collect rain water to downpipe, the gutter size is U500*300. And consider the gutter is easy get rust due to water often attach the gutter, we enhanced the materials to be bigger thickness 8mm, and use special galvanized steel material.

Downpipe: The rain water drainage by pvc downpipe, the pipe diameter is 110mm.

Door: The workshop is used to produce some big products with big height size, and consider factory owner may expend his export business to other country, the shipping container will need a big door space to get in and out the workshop, so we recommend client use a big door with size: width 6m, height 5m.

Crane: This workshop don’t have heavy goods or material need moved by over crane machine, all material can be moved easily by manpower, so we reccomment client cancel high cost over head crane to save cost, and replace it by forklift, the forklift is cheaper and can be used in other workshop as well, but crane can be only used at fixed workshop.

-

Phone

-

E-mail

-

Whatsapp

-

Top

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur